Milker: Unterschied zwischen den Versionen

(Rely on the earth worm robotic manipulator.) |

(Änderung 11477 von Jan R.B.-Wein (Diskussion) rückgängig gemacht.) |

||

| Zeile 1: | Zeile 1: | ||

| − | + | [https://forum.opensourceecology.de/viewtopic.php?f=28&t=566&p=2807#p2807| --> Discussion (Forum)] | |

| − | + | [https://github.com/faerietree/autonomous_milking_ongoing_robot --> Repository (current state/most up to date)] *work in progress* | |

| − | + | ||

| − | + | ==Motivation for an autonomous milking ongoing robot (AMOR)== | |

| − | + | <u>An autonomous system results in the following dis-/advantages:</u> | |

| − | + | * + Indepence (no more need to be there to milk morning and evening, 7days/week) | |

| − | + | * - Machine service increases | |

| − | + | * + Technical knowledge increases, hence perhaps some other good robot ideas may evolve. | |

| − | + | * + Cows/Goats/Sheep can decide themselves when to get milked. | |

| − | | | + | * + Concentrated feed can be delivered automatically and according to milk delivered. |

| − | | | + | * - Animals' possible illness not realized early enough. => Action taken too late. => Animal could die. |

| − | | | + | * - Gathering at Milking robot leaves behind a lot of unusable muddy terrain at entrance (doors in general). |

| − | | | + | * - Higher complexity in separation of milk for calves, though of course possible. |

| − | | | + | * + Driving out and in of cattle no longer necessary as animals can get milked outside. |

| − | + | * + Less material required (much shorter vacuum and milk tubes as compared to conventional non-automated distributed [at cow/goat..] milking) | |

| − | + | * ... and several others. | |

| − | + | ||

| − | + | ||

| − | + | <u>An ongoing system results in the following (dis-)advantages:</u> | |

| − | + | * - Higher complexity. | |

| − | + | * + Independance of any external supplies. | |

| − | + | ** Water (heavily dependent on environment) | |

| − | + | ** Power (Solar/Heat/Water/MFC replaces Grid) | |

| − | + | ** Food (difficult, nevertheless this is planned for later revisions of AMOR) | |

| − | + | * - Redundancy of susceptible subsystems (Electronics, in general: The more complex the system the higher the vulnerability). | |

| − | + | * + Less cabling, water pipe laying and bundled maintenance (as you can wait for enough minor errors to accumulate before taking the system apart). | |

| − | + | * ... and several others. | |

| − | + | ||

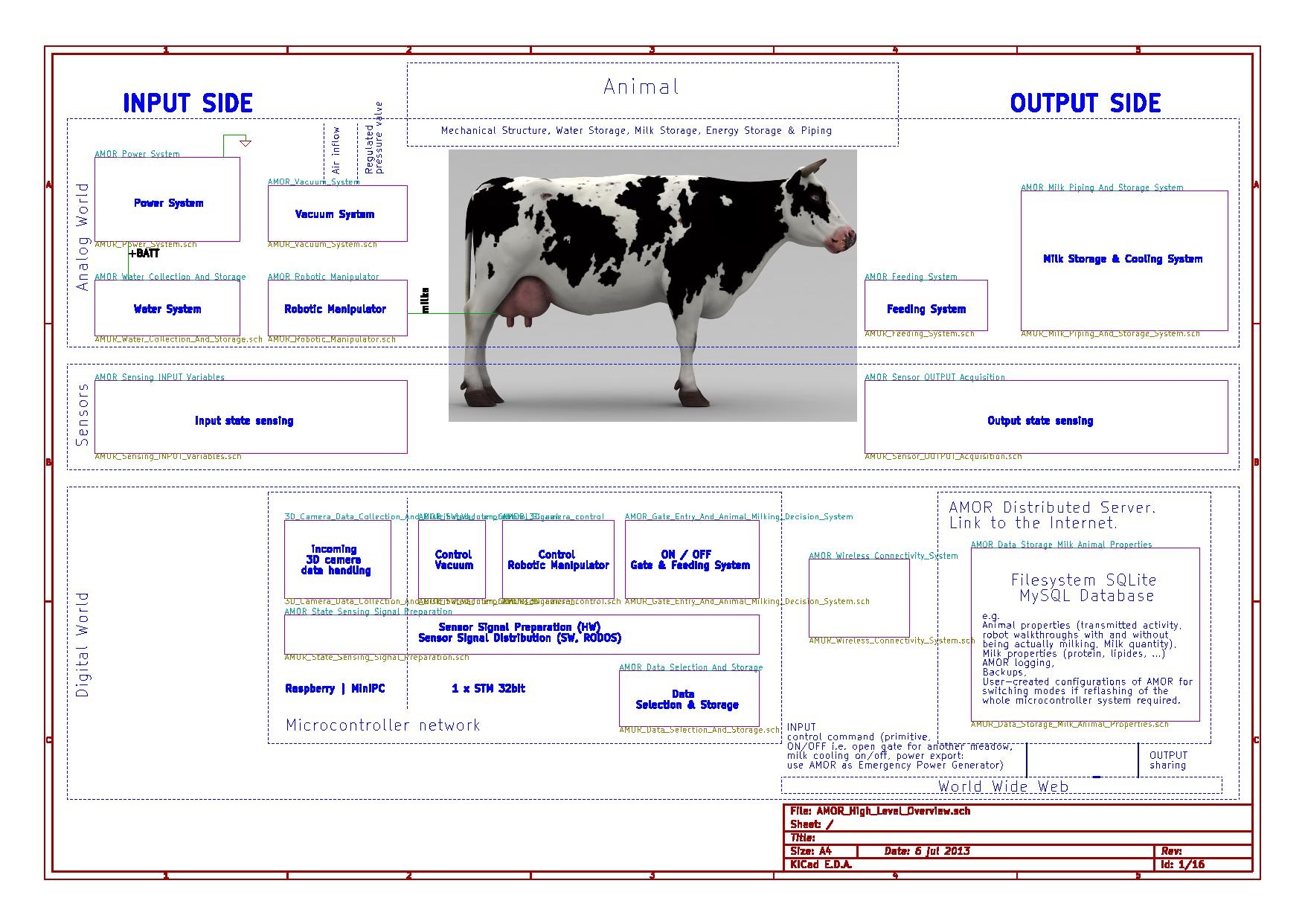

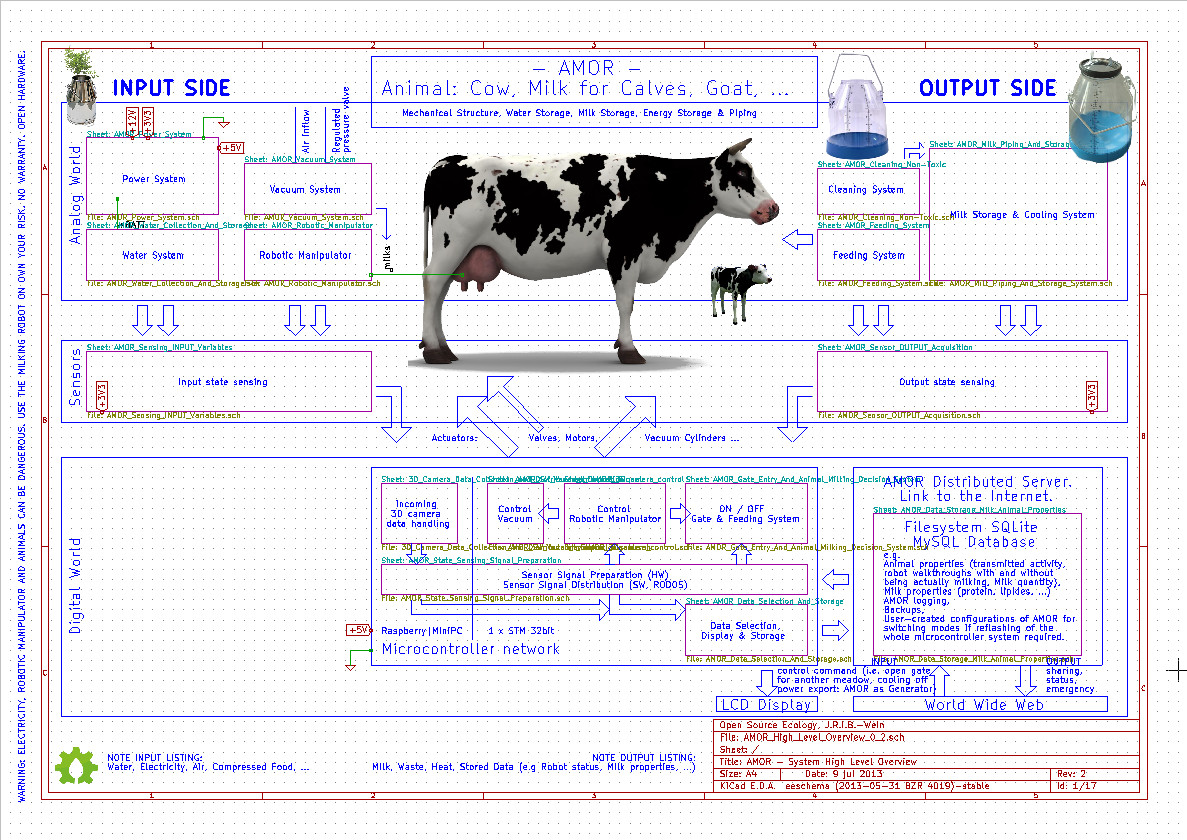

| − | + | == High Level Overview == | |

| − | + | [[File:AMOR_0_1_High_Level_Overview.pdf|alt=AMOR High Level Schematic PDF|PDF Version: REV1, Modules not linked yet.]] | |

| − | + | [[File:AMOR_0_2_High_Level_Overview.pdf|alt=AMOR High Level Schematic PDF|PDF Version: REV2, Improved & interconnected.]] | |

| − | + | [[File:AMOR_0_2_High_Level_Overview.jpg|alt=AMOR High Level Schematic (REV2)|JPG Version: REV2, Improved & interconnected.]] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ==Separation in Subproblems & Technological Difficulties == | |

| − | + | <u>AMOR of several submodules:</u> | |

| − | + | * MECHANICAL CONSTRUCTION | |

| − | + | ** - Difficult to achieve a robust, lightweight (for truck to lift) & cheap system at the same time. | |

| − | + | ** + Rain serves as a water supply and natural (ecologic) and self-sustained washing. -> So AMOR '''must be waterproof'''! | |

| − | + | * VACUUM SYSTEM | |

| − | + | ** - Difficult to be flexible in frequency (provide user settings) and keep it simple at the same time. | |

| − | + | ** + Could be used for several other functionality than milking (<strike>doors</strike>, ...). => No hydraulics needed. Update: We have settled on keeping it all electric as it's much cheaper and we need electricity anyway. | |

| − | + | ** Note: As the robotic manipulator should be flexible anyway as it could be hit by the cow, compressible air/vacuum could serve this purpose, too - but price of vacuum cylinders and the vulnerability to leakage remains a problem. | |

| − | + | ** Vacuum pump: Any pump should do, as the required vacuum levels are low and we don't have a lot of volume to keep free of gases in a mobile system because there is not much piping. | |

| − | + | * STORAGE CONSTRUCTION | |

| − | + | ** Milk | |

| − | + | ** Food | |

| − | + | ** Water | |

| − | + | ** Energy | |

| − | + | ** Database for animals milk (amount, properties, ...) | |

| − | + | ** Database for organization of the cow's fertile cycle, ... | |

| − | + | * SENSORICS | |

| − | + | ** Milk properties (flow rate, derivations of that, TODO) | |

| − | + | ** Robotic manipulator (3D camera, washing mechanism) | |

| − | + | ** Animal within milking construction => Door states. | |

| − | + | * ELECTRONICS | |

| − | + | ** Control of Doors. | |

| − | + | ** Control of Feeding (derived from amount of milk), but also accept some user constraints (lower / upper bounds for each type of food respectively). | |

| − | + | ** Control of Robotic manipulator (joints, gripper). | |

| − | + | ** Collection & storage of the stored animal & product data. | |

| − | + | * SOFTWARE | |

| − | + | ** Microcontroller programs capable of controlling at least two AMOR system blocks (stacked next to each other). | |

| − | + | ** compare ELECTRONICS. | |

| − | + | ||

| − | + | ===Mechanic structure=== | |

| − | + | The mechanic structure is free to choose. Builders might have their own preference of how to assemble a milking robot structure. Some may choose to bolt sqaure beams together, the others might prefer welding (Schweissen) steel or if they have a TIG (Tungsten) welder even aluminium. | |

| − | + | ||

| − | + | For convenience I design and post my structure as a base and hope you give back your improvements to it by mentioning it in the forum, uploading to our repository or any other possibiity you see as appropriate.. | |

| − | + | [http://www.youtube.com/watch?v=GawGF-8rVSY] | |

| − | + | ||

| − | | | + | ====Video of Prototyp 3 CAD==== |

| − | + | <u>This video demonstrates how the robotic manipulator is about to work as well as the door mechanism:</u> | |

| − | + | <video>http://www.youtube.com/watch?v=GawGF-8rVSY</video> | |

| − | + | ||

| − | + | ||

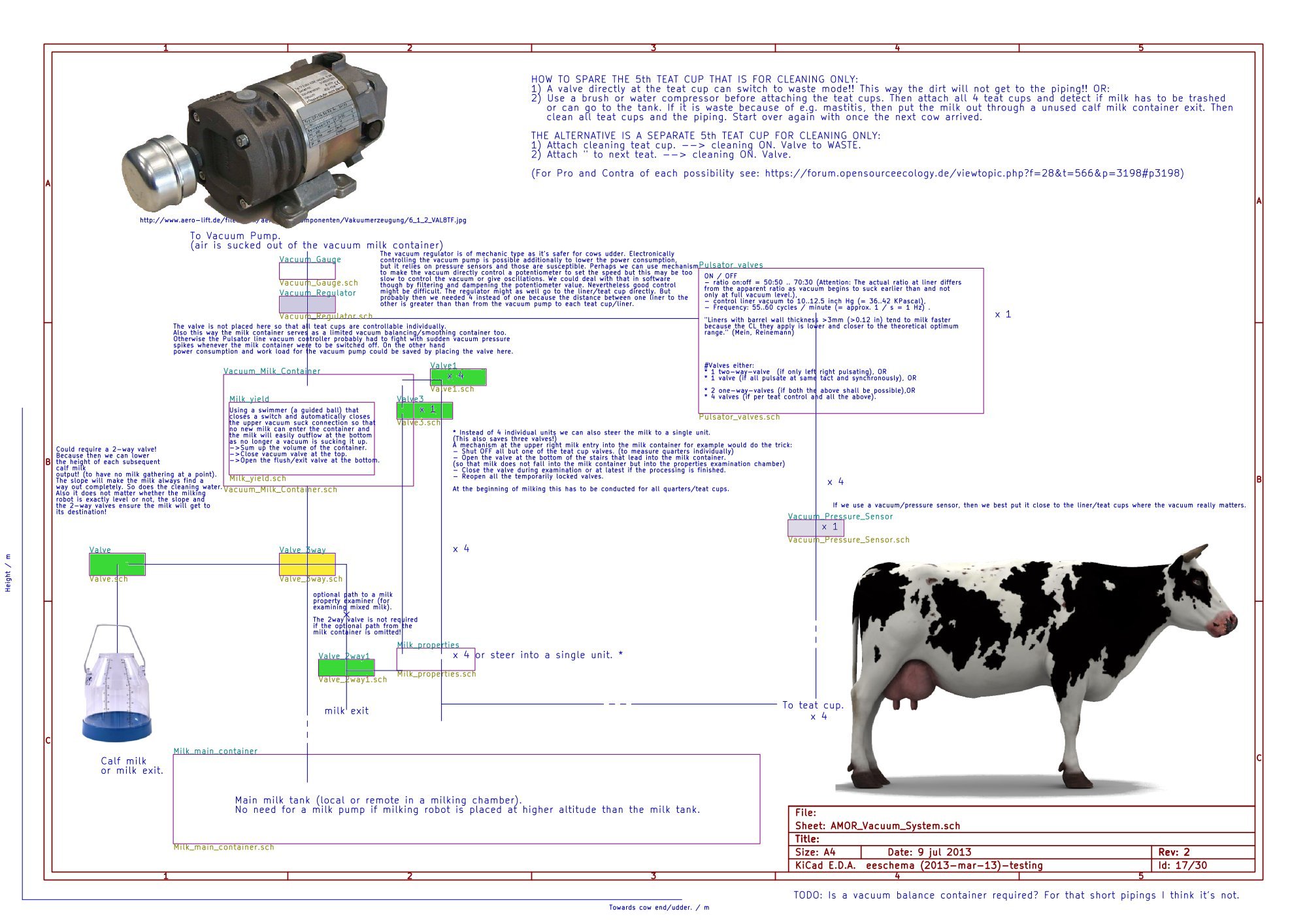

| − | + | ===Vacuum System=== | |

| − | + | [[File:AMOR_Vacuum_System.jpg| Vacuum, Piping, Valves and near by infrastructure like a milk tank. All interconnected.]] | |

| − | + | ||

| − | + | ==Power system== | |

| − | + | Several ideas for autonomous power can be found in the forum. The easiest solution for now will be to attach a truck or emergency generator (UPS) or simply an extension cord. So we need a possibility to plug it into the grid (1-phase might be too low, but let's go for that first as the vacuum system needs by far less energy in a mobile robot than in a conventional one). | |

| − | + | ||

| − | + | ||

| + | |||

| + | |||

| + | [[Category: Landwirtschaft]] [[Category: Automatisierung]] [[Category: Robotik]] [[Category: Hardware]] | ||

Version vom 20. August 2015, 21:15 Uhr

--> Discussion (Forum) --> Repository (current state/most up to date) *work in progress*

Motivation for an autonomous milking ongoing robot (AMOR)

An autonomous system results in the following dis-/advantages:

- + Indepence (no more need to be there to milk morning and evening, 7days/week)

- - Machine service increases

- + Technical knowledge increases, hence perhaps some other good robot ideas may evolve.

- + Cows/Goats/Sheep can decide themselves when to get milked.

- + Concentrated feed can be delivered automatically and according to milk delivered.

- - Animals' possible illness not realized early enough. => Action taken too late. => Animal could die.

- - Gathering at Milking robot leaves behind a lot of unusable muddy terrain at entrance (doors in general).

- - Higher complexity in separation of milk for calves, though of course possible.

- + Driving out and in of cattle no longer necessary as animals can get milked outside.

- + Less material required (much shorter vacuum and milk tubes as compared to conventional non-automated distributed [at cow/goat..] milking)

- ... and several others.

An ongoing system results in the following (dis-)advantages:

- - Higher complexity.

- + Independance of any external supplies.

** Water (heavily dependent on environment) ** Power (Solar/Heat/Water/MFC replaces Grid) ** Food (difficult, nevertheless this is planned for later revisions of AMOR)

- - Redundancy of susceptible subsystems (Electronics, in general: The more complex the system the higher the vulnerability).

- + Less cabling, water pipe laying and bundled maintenance (as you can wait for enough minor errors to accumulate before taking the system apart).

- ... and several others.

High Level Overview

PDF Version: REV2, Improved & interconnected.

PDF Version: REV2, Improved & interconnected.

Separation in Subproblems & Technological Difficulties

AMOR of several submodules:

- MECHANICAL CONSTRUCTION

- - Difficult to achieve a robust, lightweight (for truck to lift) & cheap system at the same time.

- + Rain serves as a water supply and natural (ecologic) and self-sustained washing. -> So AMOR must be waterproof!

- VACUUM SYSTEM

- - Difficult to be flexible in frequency (provide user settings) and keep it simple at the same time.

- + Could be used for several other functionality than milking (

doors, ...). => No hydraulics needed. Update: We have settled on keeping it all electric as it's much cheaper and we need electricity anyway. - Note: As the robotic manipulator should be flexible anyway as it could be hit by the cow, compressible air/vacuum could serve this purpose, too - but price of vacuum cylinders and the vulnerability to leakage remains a problem.

- Vacuum pump: Any pump should do, as the required vacuum levels are low and we don't have a lot of volume to keep free of gases in a mobile system because there is not much piping.

- STORAGE CONSTRUCTION

- Milk

- Food

- Water

- Energy

- Database for animals milk (amount, properties, ...)

- Database for organization of the cow's fertile cycle, ...

- SENSORICS

- Milk properties (flow rate, derivations of that, TODO)

- Robotic manipulator (3D camera, washing mechanism)

- Animal within milking construction => Door states.

- ELECTRONICS

- Control of Doors.

- Control of Feeding (derived from amount of milk), but also accept some user constraints (lower / upper bounds for each type of food respectively).

- Control of Robotic manipulator (joints, gripper).

- Collection & storage of the stored animal & product data.

- SOFTWARE

- Microcontroller programs capable of controlling at least two AMOR system blocks (stacked next to each other).

- compare ELECTRONICS.

Mechanic structure

The mechanic structure is free to choose. Builders might have their own preference of how to assemble a milking robot structure. Some may choose to bolt sqaure beams together, the others might prefer welding (Schweissen) steel or if they have a TIG (Tungsten) welder even aluminium.

For convenience I design and post my structure as a base and hope you give back your improvements to it by mentioning it in the forum, uploading to our repository or any other possibiity you see as appropriate.. [1]

Video of Prototyp 3 CAD

This video demonstrates how the robotic manipulator is about to work as well as the door mechanism: <video>http://www.youtube.com/watch?v=GawGF-8rVSY</video>

Vacuum System

Power system

Several ideas for autonomous power can be found in the forum. The easiest solution for now will be to attach a truck or emergency generator (UPS) or simply an extension cord. So we need a possibility to plug it into the grid (1-phase might be too low, but let's go for that first as the vacuum system needs by far less energy in a mobile robot than in a conventional one).