Wind Turbine/en

Status

The wind turbine is in the research phase of product development. We are focusing on the TiVA-System (Tiny Vertical Axis Wind Turbine) right now and developing the Wilssen controller for it.

Introduction

We are developing an open source wind turbine with an agile open collaboration.

TiVA and wind turbine specifications started with a joint development venture between etemu.com and Apollo-NG. All information is released open source and for free, for a better world and for the fun of open collaboration. (CC BY-SA-NC)

TiVA

Research and development is currently concentrated onto TiVA, a tiny wind turbine prototyping platform. With this very small turbine, we can easily change parts, try out new ideas and increase the quality of the design on a small scale in a fast and inexpensive way. Please have a look at the TiVA page for further information.

Team

If you want to participate, just get in touch via our Forum or just hit Shure an e-mail. :)

- Alex Shure – lead designer, research and development, modeling, prototyping

- Mario Grunau - 3D modelling (Autodesk Inventor, Maxon Cinema 4D)

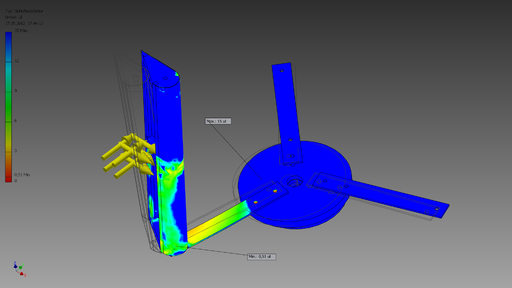

- Achmed Touni - 3D modelling (FreeCAD, Blender3D), simulation (OpenFOAM, Ansys)

- Nikolay Georgiev - communication and organization

- Benjamin Rudtsch - Wilssen, software development

- Leon Rische - Wilssen, software development

Open Tasks

You can help us with any improvement on the project or with the following specific tasks:

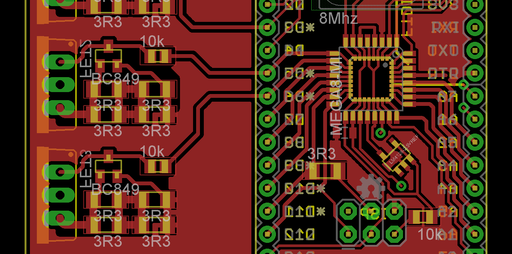

Development of Wilssen

The Wireless / Wind Logging System for Sourcing ENergy - Controller is monitoring and controlling all parameters. Wilssen is the brain of the wind turbines (+TiVAs!) and checks all the voltages at any time the wind turbine is generating power.

See the current open github issues: https://github.com/etemu/wilssen/issues?state=open

Others

- Design a mold for casting the alternator's stator

- 3D Models and Simulation (Achmed and Mario are working on it)

- Calculations for the forces at the bearing points and the mounting point

- LED drivers, controllable constant current sources for the high power LEDs

- (many more soon to come)

We still need the following materials for our first prototypes:

- Round sheets of metal for the alternators

- Plywood (Multiplex)

- Tools for the lathe, boring bar, inserts..

- Aluminium sheets for the wings

- Polyester or epoxy resin and hardener + filler

- Paint which can be sprayed, should be a sealing one for outdoors

- Cases for the electronics, IP66<

- Neodymium magnets, preferably 15x5mm<

- Enameled copper wire aka. magnet wire, with a diameter of 0.4 - 1.0mm

- Electric planer

- Aluminium or stainless steel tubes, e.g. 12x8mm for TiVA

Please get in touch with Alex Shure if you want to donate any material or machine which could come in handy for us.

Roadmap / Log

- 20120211 Alex Shure Start of "Open Agile SCRUM GVCS machine development" mailing list, Nikolay Georgiev sent an E-Mail to some OSE:E members - We begin to discuss the OSE:E project of constructing a wind turbine

- 20120222 Alex Shure First online meeting on the OSE:E project "develop a wind turbine" in mumble

- 20120311 Alex Shure I had a 6 hour meeting with a German wind turbine technician who works in QS where we discussed various aspects, advantages and disadvantages of horizontal and vertical axis wind turbines.

- 20120324 Alex Shure Had an online conference in mumble and spoke with Chrono, founder of the Apollo-NG[1] project. Chrono has experience in electronics, especially in integrated low power switching power supplies and mobile energy supplies. He is transforming a van into a mobile hackerspace, powered by renewable energy, totally off the grid.

- 20120325 Alex Shure Phone conference with Detlef Schmitz from the solar car team Heliodet; Detlef offered to build one small wind turbine prototype. He has contacts also with engineers and technicians form the solar car project, especially students from the FH/uni in Bochum.

- 20120326 Alex Shure Added the EVA wind turbine design. We could develop a VAWT which can be optionally equipped with the EVAwt features. The biggest disadvantage is the design issue with the top cover plate: with the EVAwt design, I can't think of an easy way to span the cables from the top for now.

- 20120327 Alex Shure chrono added a pad on Apollo for collaboration

- 20120328 Alex Shure Calculations

- 20120329 Alex Shure contacted Bernd from http://www.daswindrad.de

- 20120330 Alex Shure Added the TiVA page to the wiki and further designed the concept in the etherpad..

- 20120331 Alex Shure chrono moved the content from the pad at Apollo-NG into the dokuwiki at Apollo-NG. I split the TiVA parts and copied them to a wiki page here at OSE

- 20120404 Alex Shure Researched about copper losses in the enameled copper wire windings, let's use 0.45 - 1 mm wire.

- 20120405 Alex Shure I updated the TiVA wiki entry at OSE with a full BOM for a very first prototype, including sheet material for the negative form, painting and so on. Also got Mario on board, who has experience in 3D modeling.

- 20120406 Alex Shure Meeting with Mario, 3D modelling session in Autodesk Inventor.

- 20120407 Alex Shure Met M. Klein, CEO of Wezek GmbH (engineering, automation) and spoke about waterproof cases for the electronics.

- 20120408 Alex Shure Specification for TiVA's alternator outlined. Diameter reduced to less than 200 mm, 1 phase alternator design is preferred due to less costs and the low power demand.

- 20120409 Alex Shure Finished the calculations of TiVA's alternator. 16 round magnets, 16 coil segments, switchable from 8s1p up to 1s8p, calculated efficiency after rectification is above 90% for low loads.

- 20120410 Alex Shure We should stick to symmetric wing profiles if we go for a Darrieus style lift rotor, because those would be the easiest to fabricate. Researching on some NACA profiles now. Wings of the V-Rotor should incorporate a metal strip sandwiched between the two halves of the wing for the easiest and most rigid wing fixation method.

- 20120412 Alex Shure Fabricated three wings for TiVA out of solid wood (spruce)

- 20120413 Alex Shure Full day working session in the shop for TiVA, made a hub, cut plywood, laminated the base, machined bearing seats on the lathe ...

- 20120414 Alex Shure Glued the cut plywood together, trimmed the edges, made another pass on the lathe after the lamination, to make sure everything is perfectly balanced.

- 20120415 Alex Shure Press-fit the bearings into the hub, tested the starting torque of the assembled hub with the bearings in place: not measurable with a 0.1 N scale -> good! Bought a stand air ventilator for testing purposes.

- 20120416 Alex Shure Ordered parts for the electronics + mechanics: Bearings (DIN 6003), Schottky diodes, M6 - M12 V2A stainless steel bolts and nuts, ...

- 20120417 Alex Shure Bought 5 kg of 0,45 mm diameter enameled copper wire (aka. magnet wire) for about 100,00 EUR. Does anybody have a cheap source for copper wire and magnets?

- 20120422 Alex Shure Tested NACA0018 profiles at various angles: NACA0018 profiles aren't self starting at low angles. Aiming for a Lenz2 profile now.

- 20120426 Alex Shure Designed the alternator rotor assembly, sketched the model in SketchUp.

- 20120429 Alex Shure Ordered passive and active electronic parts.

- 20120507 Alex Shure Rotor assembly just got reconstructed: one less part which is turned on the lathe + implemented the alternator stacking feature.

- 20120508 Alex Shure Achmed is working on a FreeCAD model and will then make a mesh for OpenFOAM, an open source CFD software package.

- 20120510 Alex Shure Meeting with Mario, instructed him about the 3D model. We also agreed on leaving the NACA lift-only profiles for TiVA behind, as the Reynolds number is just too high for these small dimensions.

- 20120512 Alex Shure 3D modelling session with Mario, finished TiVA's rotor base and began with the Lenz2 lift/drag hybrid wing profile.

- Nov 2012 Alex Shure I stopped using the wiki as a crude archive and did not protocol everything which happened since May '12. A severe amount of time was put into other parts and projects of OSEG. All in all, we have agreed on getting a real project management suite online and use it for this and other projects of OSEG.

General design outlines

The wind turbine should be loosely designed according to the OSE Core Values except points 8 and 9, which demand high performance and equal to or higher than industrial efficiency [3]

In addition to the OSE Core Values, the wind turbine should be safe to operate, e.g. have a suitable safety factor in all structural calculations, proper isolation to prevent an electric shock.

Assembly height

The complete assembly of rotor and mast should not be higher than 10 m. If regional communities permit higher masts, the maximum height must not exceed 20 m, to avoid national and ICAO air traffic security issues and legal obligations to carry warning lights and report about their functionality. There are various restrictions in Germany present which depend on the size and location of a wind turbine:

Verfahrensfrei sind Windenergieanlagen bis zu einer Höhe von 10 m[4]. In Mischgebieten[5] darf nachts ein Lärmrichtwert von 45 dB(A) nicht überschritten werden[6]. Zu den Genehmigungsverfahren sei gesagt, dass die Landesbauordnung der jeweiligen Bundesländer / Kommunen unterschiedlich ist, also sollte man beim Bauamt nachfragen.

Size

We won't start with a turbine greater than 4 m² due to restrictions in Europe pointed out by Detlef Schmitz. A wind surface of 4 m² equals a 2 m diameter rotor with a height of 2 m. Hint: In every wind condition, a 1 m diameter VAWT with a height of 4 m (4m²) is mor

- ↑ Tip Speed Ratio

- ↑ work in progress

- ↑ OSE Core Values points 8 and 9 demand a high performance and equal to or higher than industrial efficiency but the efficiency of a highly sophisticated industrial, FEA designed and airflow-simulated, wind tunnel tested model can't be matched by a diy design.

- ↑ Nummer 22 des Anhangs zu Paragraph 50 Abs. 1 LBO

- ↑ Mischgebiet bedeutet gleichwertige Wohn- und Gewerbenutzung

- ↑ Auszug Windfibel Baden-Württemberg