Wind Logging System for Sourcing ENergy – WiLSSEN

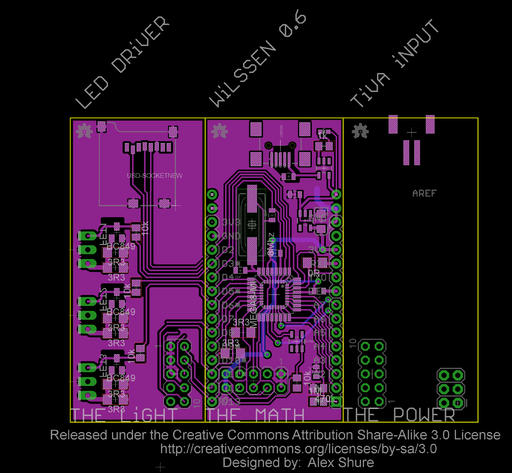

The Wireless / Wind Logging System for Sourcing ENergy - Controller is a multi-purpose prototyping platform for (but not limited to) renewable energies. E.g. It can be used for monitoring all electrical parameters of a wind turbine generator or to sense the temperature in a room/machine/garden/aquaponic system wirelessly for over one year on two AA-batteries.[1]

Wilssen is the brain of TiVA and checks all the voltages at any time the wind turbine is generating power.

Team

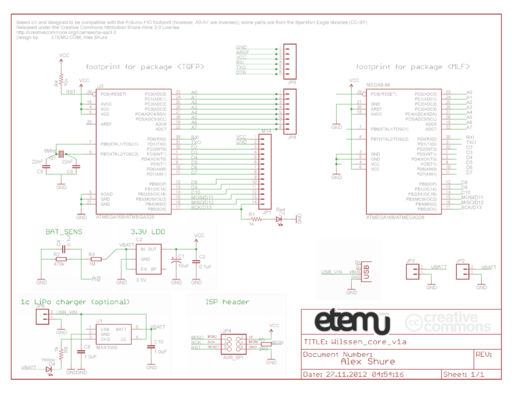

- Alex Shure – lead designer, schematics, PCB layout

- Achmed Touni - waveform sampling algorithm, FFT

- Benjamin Rudtsch - hard- and software development

- Leon Rische - software development: LED code, visual feedback functions

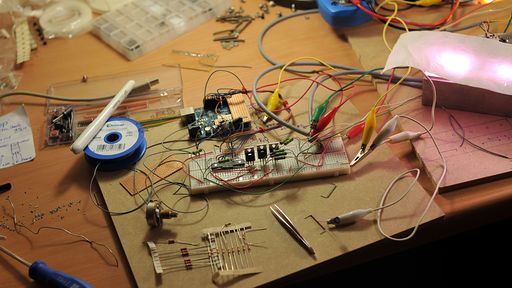

Development

IRC: #OSEG on freenode

Git repository: Contains the source code, schematics, layouts and documentation (see latest commits) - feel free to add issues or fork us. :-)

Open issues: Any issues / bugs / features of Wilssen's hard- and software.

Any Questions may be asked in the Forum.

Hardware:

- NRF24L01+ 2.4Ghz wireless communication. Mesh networking would be awesome :) - cluster networking should be possible with this Arduino library: http://maniacbug.wordpress.com/2012/03/30/rf24network/

- RGB LED PWM output (3 channels, R+G+B)

Current sensing:

- Passive on-board shunt resistor (only for low currents) via OpAmp -> 10bit ADC

- Allegro ACS712 integrated hall sensor with drift compensation, 1.2 mOhms (5A, 20A, 50A versions available) -> 10bit ADC

Voltage sensing:

- Passive resistor divider with high impedance coupling -> 10bit< ADC

- optional: decoupled voltage sensing via IC / galvanic isolation.

- (tbd) Option for waveform sampling, softscope (e.g. output the waveform at a specified sample interval in 10bit via serial over the wireless link)

- (tbd) Logging on MicroSD

- (tbd) Charging circuit for 4 NiMH cells / 1 lead acid gel battery.

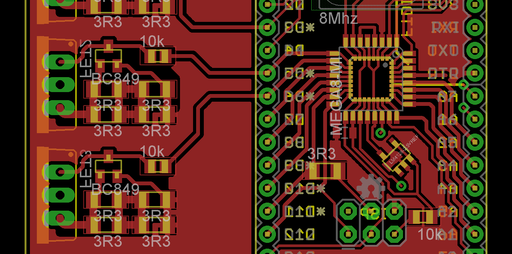

We chose the Atmel Atmega168/328 series for the main controller, due to the great Arduino community.

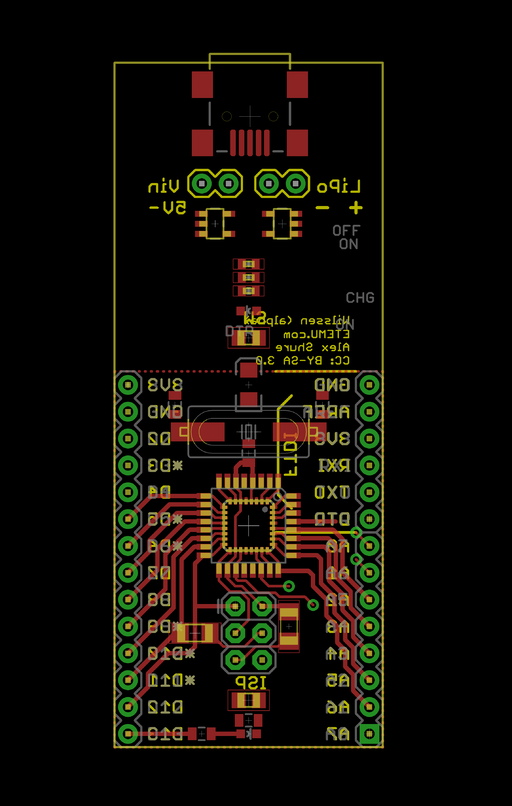

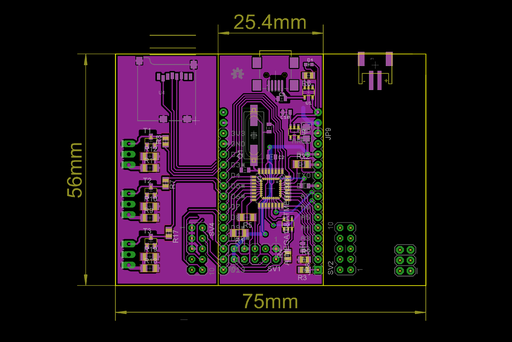

Main Controller: Wilssen core

- Optiboot bootloader compatible, thus Arduino compatible

- Main MCU: Atmel Atmega168, Atmega328

Software

Microcontroller

- RGB LED library

- Logic power supply battery voltage monitoring / watchdog

- Variable voltage protection routine

- Variable current protection routine

- Wireless communication protocol

- RPM calculation from alternator frequency

- MicroSD logging

- Sleep mode

- (tbd)

Computer

- GUI for real time analysis

Draft for usage as a multi-phase alternator controller

Controlled parallel-serial generator switching system: A turbine could be actively regulated by Wilssen's load-balancing features, such as increasing or decreasing the load, up to the freewheeling no-load open-circuit state, or reconfiguring the alternator windings on the fly. As the coils are wound at least quadfilar, there are various possibilities to connect the windings.

Brainstorming (deprecated)

What micro controller platform should we choose for Wilssen?

- AVR: Atmel ATmega328 (AU, PU) (pico power series) (8bit)

- MSP430: Value line, e.g. MSP430G2231IPN14 (16bit)

One MSP430G2231IPN14 16bit micro controller could work for ages, at as low as 2V, it may consume 1 mW = 1/1000 W. Typical no-load best-case values from the MSP430 datasheet:

0.1 µA RAM retention

0.4 µA Standby mode (VLO)

0.7 µA real-time clock mode

220 µA / MIPS active

Excellent values! An 8-bit Arduino looks pretty old school against these numbers. ;-)

pro MSP430, con AVR/Arduino:

- the price! can be bought with a programmer for USD 4.30 vs Arduino USD 25.00 or a third-party Arduino for maybe USD 18.00 - This is a serious difference.

- even the single MCUs are cheaper, also, the AtMegas for an Arduino bootloader are hard to get.

- less external parts for operation at high speeds, Arduino/atmega168 and 328 need an external oscillator to operate at full speed (16 Mhz)

- runs stable over a wide range of input voltage down to 1.8V

- an excellent sleep mode with RAM retention at only 0.1µA and great power efficiency. 220µA in full operation mode is an excellent figure for off-grid low energy applications. Almost no load to the turbine. Can also be powered by a "Joule Thief" and a single old AA battery, or just two old AA cells in series (3V). That should last for ages, at a constant current of 0.25 mA and an old battery of 1000 mAh, the unit will still run for 180 days, and the MSP430 can be operated with a supply voltage as low as 1.8V.

con MSP430:

- less memory, but this depends on the package, (there are top-end msp430 processors which cost less than $1 vs an ever-expensive-avr)

- less libraries available, smaller community

A nice solution: => Write clean C-code and let it be compatible with MSP430 and AVR compilers. Some Arduino projects were easily ported to the MSP430.

Draft for a closed control loop:

example values: V_out = 16V V_sys = variable, depending on load V_gen = variable, depending on wind input and switching and system voltage

- monitor V_out. if V_sys less than Vout, then

- serialize the windings,

- still to little voltage? -> if generator-coil-form-1 and many points are broken out of the coil, then serialize them in a pattern to gain more voltage

- too much voltage? never mind, either wait for a small period of time because the rotor has a mass and stores kinetic energy, which first has to be converted by the "new serial-wound-generator". the speed will drop eventually and the voltage will stabilize itself, OR

- rapidly switch between parallel and serial modes (if the load, e.g. the synchronous rectifier, can cope with the spikes (inductive..) and has appropriate switching abilities) and thus form an sort of automatic pulse width modulated, regulated, operation mode.

- if V_sys + Vdelta,hysteresis >Vout, then

- switch to parallel mode

other cases:

- any of the voltages exceed e.g. 56V: emergency mode:

- either make the generator windings float or short them.

- !! shorting may not be an option. only with temperature control of the generator and the semiconductors due to the heat generated at a shortcut.!!

- If all batteries are loaded and the current user power consumption level is minimal, the power surplus of the turbine should be fed into high power LEDs, pointing upwards from the base, lighting the turbine. This adds to protect the system of an unbalanced situation, when more power is generated than reasonably consume- or storable and at the same time to signal, that we still have more energy to share, inviting people to join, in a friendly and beautiful manner.

- In general, LEDs should also be incorporated at the controller: the controller should have a mosfet-switched control output, one 3W RGB led should display the wind speed or the battery voltage.. (on a scale from red to green and strobe patterns)

- 'high-tech' electronic idea: dual rotor on single pole design, counter rotating, brush-less royer converter, doubled rpm, less poles, switching power supply is already build in due to the royer converter, coil-in-coil, core coupling, voltage output may be quite high from the start. lower electrical efficiency? downside: needs IP67 protected circuits on both the rotor and the stator of the royer converter. upside: output voltage could be regulated on-board. also, input voltage may be very low depending on the setup.

- variation: a rotor with lift-type wings on top and a rotor with drag-type wings at the bottom. thus the lower rotor gains speed at lower wind speeds but has a top end speed of approx. lift-type/2, while the lift-type wing still accelerates in high wind speed conditions.

- ↑ With one temperature read and transmitted every two minutes

- ↑ Printed Circuit Board

- ↑ 100x160mm - Eurocard is a European standard format for PCB cards, see http://en.wikipedia.org/wiki/Eurocard_(printed_circuit_board)]