Milker: Unterschied zwischen den Versionen

(Änderung 11477 von Jan R.B.-Wein (Diskussion) rückgängig gemacht.) |

(Rely on the earth worm robotic manipulator instead of a custom design.) |

||

| Zeile 1: | Zeile 1: | ||

[https://forum.opensourceecology.de/viewtopic.php?f=28&t=566&p=2807#p2807| --> Discussion (Forum)] | [https://forum.opensourceecology.de/viewtopic.php?f=28&t=566&p=2807#p2807| --> Discussion (Forum)] | ||

[https://github.com/faerietree/autonomous_milking_ongoing_robot --> Repository (current state/most up to date)] *work in progress* | [https://github.com/faerietree/autonomous_milking_ongoing_robot --> Repository (current state/most up to date)] *work in progress* | ||

| + | |||

| + | '''Fundamental development change August 2015:''' | ||

| + | With milk amount increasing, therefore falling prices (which in itself may not be a bad thing, because it makes milk readily available) there is no survival chance for many (often small) farms if not a vast increase in efficiency is achieved. Time runs out, the world state is worsening too. | ||

| + | |||

| + | On this background, AMOR now relies on an Earth worm robot, which replaces several custom machine designs with one standard construction whose functionality changes depending on the program. Tribute to Jef Murray, a skilled artist that has left our case too early. | ||

| + | |||

| + | '''Reasons:''' | ||

| + | Reason is to prevent a thousand custom designs, replacing it with one universal robot design (and thus saving a lot of hardware + software development, documentation, testing, ...). | ||

| + | |||

| + | Secondary reason is that the <a href="https://www.youtube.com/watch?v=GawGF-8rVSY">previous milking robotic manipulator design</a> is not certain to work with a real animal due to the limited workspace and the difficult base construction which requires reattachment (thus remachining) if there are more sizes and kinds of animals to be milked, e.g. goat or sheep teats pointing sidewards currently are hard to dock to. | ||

==Motivation for an autonomous milking ongoing robot (AMOR)== | ==Motivation for an autonomous milking ongoing robot (AMOR)== | ||

Version vom 20. August 2015, 21:16 Uhr

--> Discussion (Forum) --> Repository (current state/most up to date) *work in progress*

Fundamental development change August 2015: With milk amount increasing, therefore falling prices (which in itself may not be a bad thing, because it makes milk readily available) there is no survival chance for many (often small) farms if not a vast increase in efficiency is achieved. Time runs out, the world state is worsening too.

On this background, AMOR now relies on an Earth worm robot, which replaces several custom machine designs with one standard construction whose functionality changes depending on the program. Tribute to Jef Murray, a skilled artist that has left our case too early.

Reasons: Reason is to prevent a thousand custom designs, replacing it with one universal robot design (and thus saving a lot of hardware + software development, documentation, testing, ...).

Secondary reason is that the <a href="https://www.youtube.com/watch?v=GawGF-8rVSY">previous milking robotic manipulator design</a> is not certain to work with a real animal due to the limited workspace and the difficult base construction which requires reattachment (thus remachining) if there are more sizes and kinds of animals to be milked, e.g. goat or sheep teats pointing sidewards currently are hard to dock to.

Motivation for an autonomous milking ongoing robot (AMOR)

An autonomous system results in the following dis-/advantages:

- + Indepence (no more need to be there to milk morning and evening, 7days/week)

- - Machine service increases

- + Technical knowledge increases, hence perhaps some other good robot ideas may evolve.

- + Cows/Goats/Sheep can decide themselves when to get milked.

- + Concentrated feed can be delivered automatically and according to milk delivered.

- - Animals' possible illness not realized early enough. => Action taken too late. => Animal could die.

- - Gathering at Milking robot leaves behind a lot of unusable muddy terrain at entrance (doors in general).

- - Higher complexity in separation of milk for calves, though of course possible.

- + Driving out and in of cattle no longer necessary as animals can get milked outside.

- + Less material required (much shorter vacuum and milk tubes as compared to conventional non-automated distributed [at cow/goat..] milking)

- ... and several others.

An ongoing system results in the following (dis-)advantages:

- - Higher complexity.

- + Independance of any external supplies.

** Water (heavily dependent on environment) ** Power (Solar/Heat/Water/MFC replaces Grid) ** Food (difficult, nevertheless this is planned for later revisions of AMOR)

- - Redundancy of susceptible subsystems (Electronics, in general: The more complex the system the higher the vulnerability).

- + Less cabling, water pipe laying and bundled maintenance (as you can wait for enough minor errors to accumulate before taking the system apart).

- ... and several others.

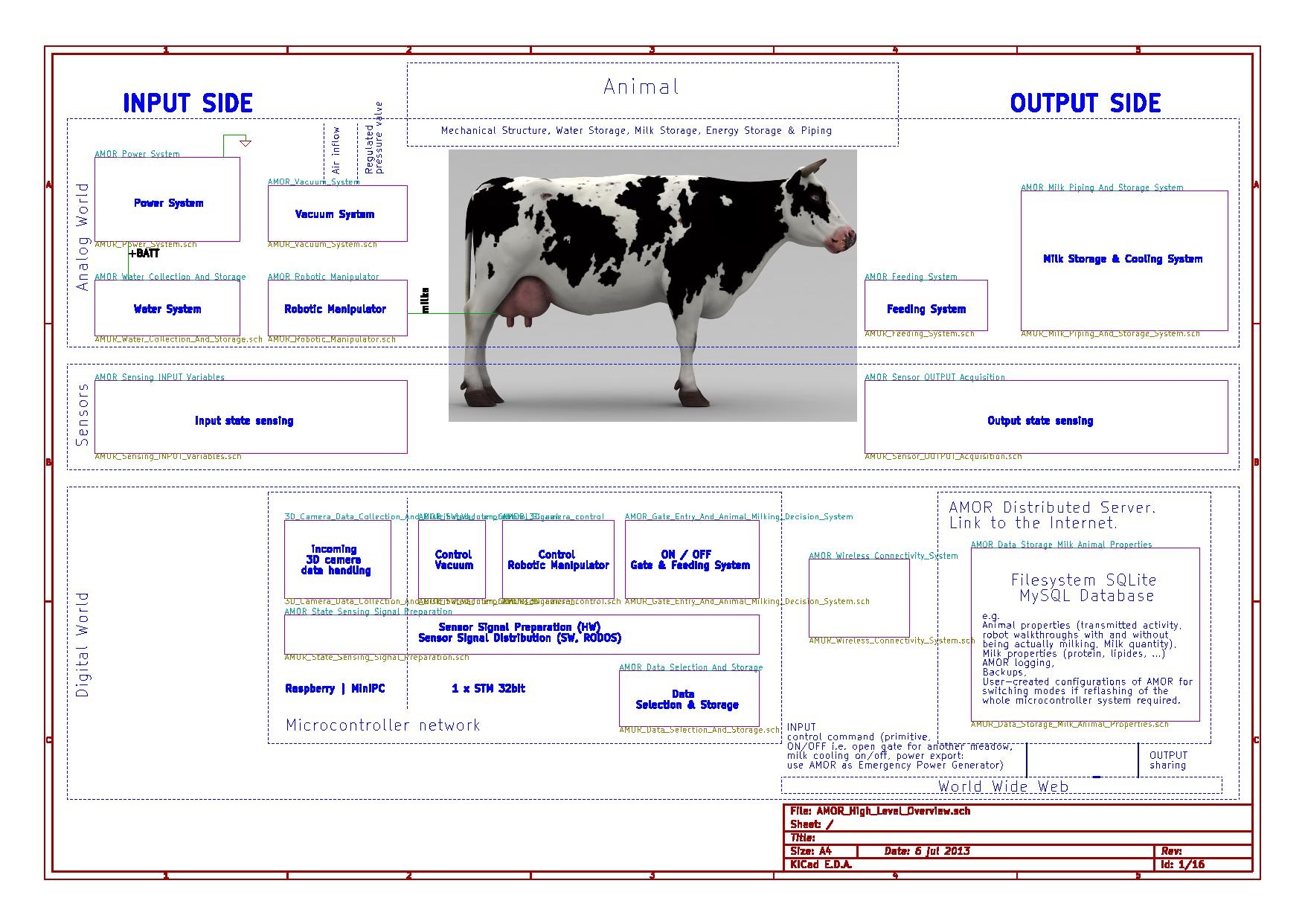

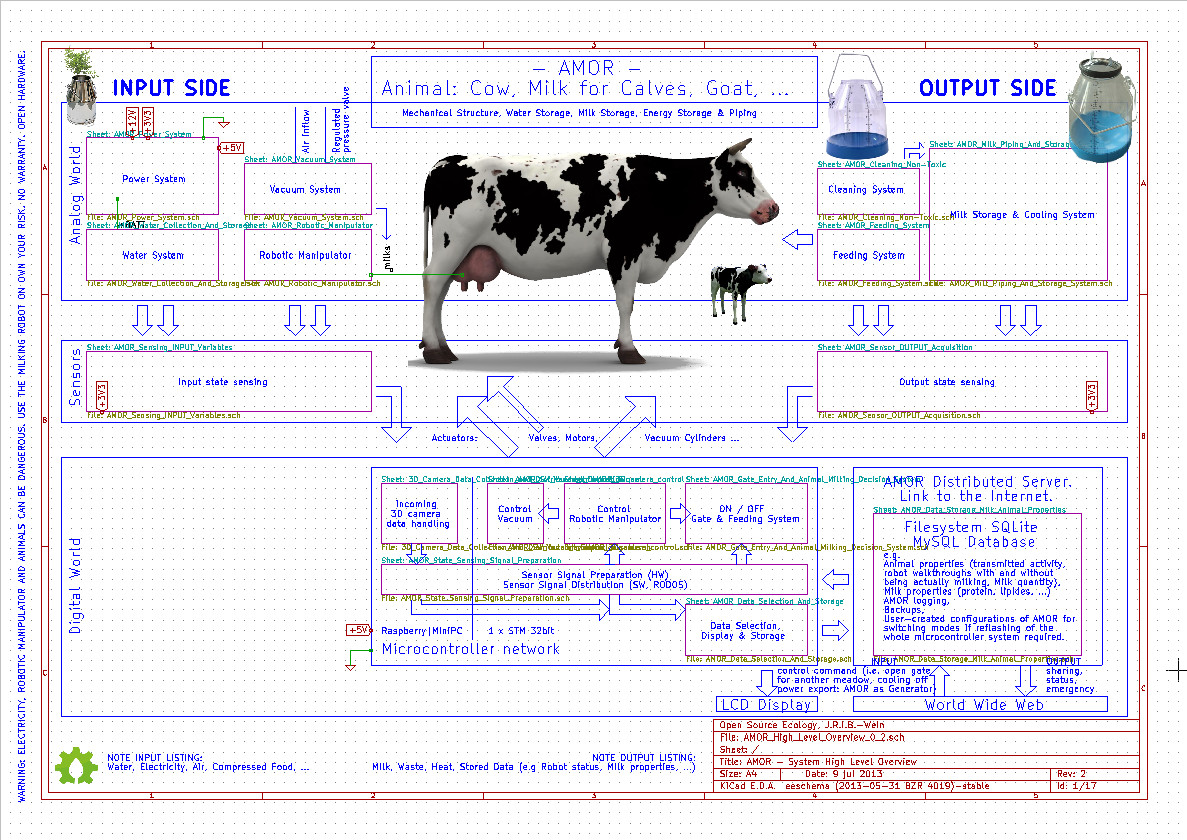

High Level Overview

PDF Version: REV2, Improved & interconnected.

PDF Version: REV2, Improved & interconnected.

Separation in Subproblems & Technological Difficulties

AMOR of several submodules:

- MECHANICAL CONSTRUCTION

- - Difficult to achieve a robust, lightweight (for truck to lift) & cheap system at the same time.

- + Rain serves as a water supply and natural (ecologic) and self-sustained washing. -> So AMOR must be waterproof!

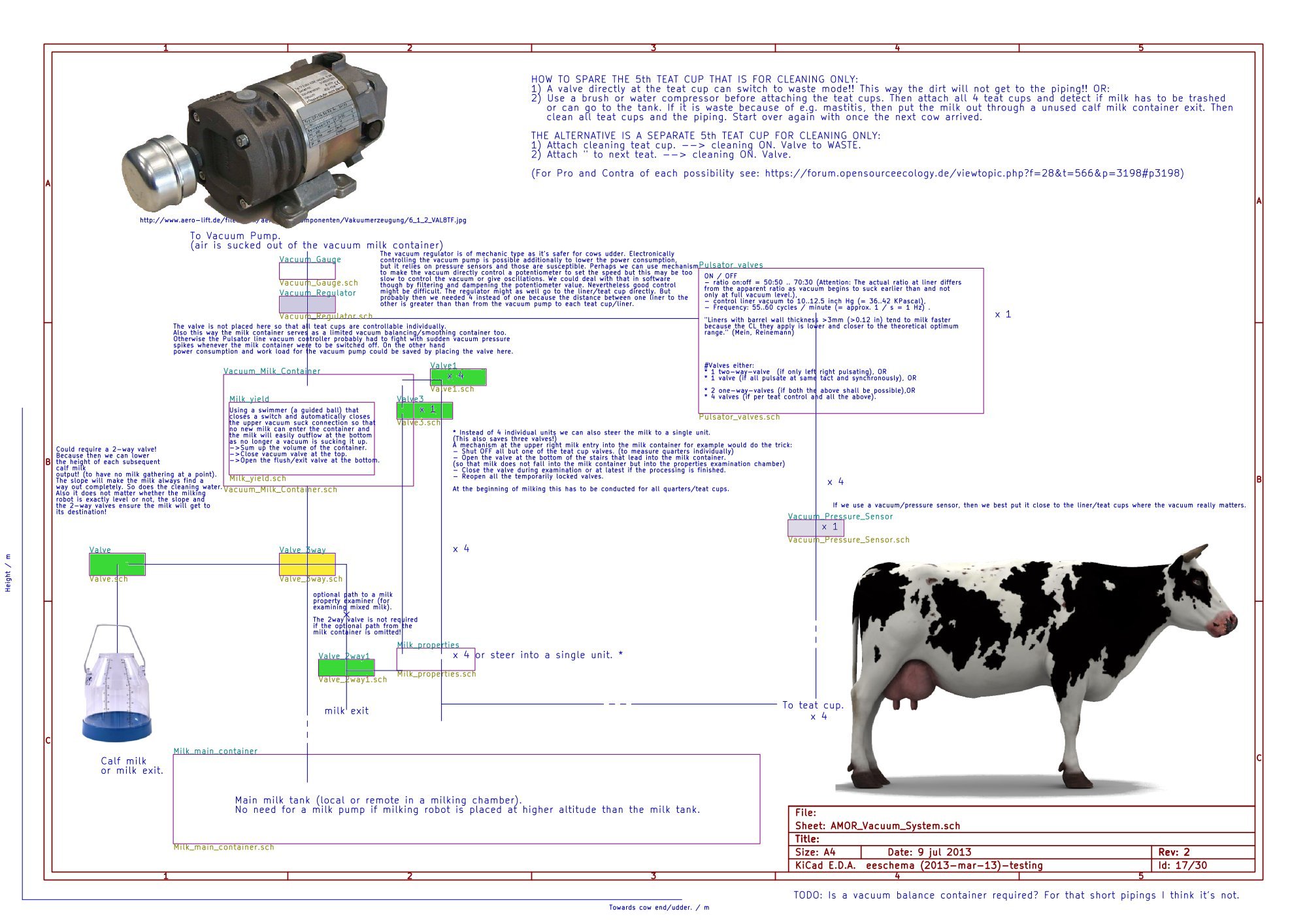

- VACUUM SYSTEM

- - Difficult to be flexible in frequency (provide user settings) and keep it simple at the same time.

- + Could be used for several other functionality than milking (

doors, ...). => No hydraulics needed. Update: We have settled on keeping it all electric as it's much cheaper and we need electricity anyway. - Note: As the robotic manipulator should be flexible anyway as it could be hit by the cow, compressible air/vacuum could serve this purpose, too - but price of vacuum cylinders and the vulnerability to leakage remains a problem.

- Vacuum pump: Any pump should do, as the required vacuum levels are low and we don't have a lot of volume to keep free of gases in a mobile system because there is not much piping.

- STORAGE CONSTRUCTION

- Milk

- Food

- Water

- Energy

- Database for animals milk (amount, properties, ...)

- Database for organization of the cow's fertile cycle, ...

- SENSORICS

- Milk properties (flow rate, derivations of that, TODO)

- Robotic manipulator (3D camera, washing mechanism)

- Animal within milking construction => Door states.

- ELECTRONICS

- Control of Doors.

- Control of Feeding (derived from amount of milk), but also accept some user constraints (lower / upper bounds for each type of food respectively).

- Control of Robotic manipulator (joints, gripper).

- Collection & storage of the stored animal & product data.

- SOFTWARE

- Microcontroller programs capable of controlling at least two AMOR system blocks (stacked next to each other).

- compare ELECTRONICS.

Mechanic structure

The mechanic structure is free to choose. Builders might have their own preference of how to assemble a milking robot structure. Some may choose to bolt sqaure beams together, the others might prefer welding (Schweissen) steel or if they have a TIG (Tungsten) welder even aluminium.

For convenience I design and post my structure as a base and hope you give back your improvements to it by mentioning it in the forum, uploading to our repository or any other possibiity you see as appropriate.. [1]

Video of Prototyp 3 CAD

This video demonstrates how the robotic manipulator is about to work as well as the door mechanism: <video>http://www.youtube.com/watch?v=GawGF-8rVSY</video>

Vacuum System

Power system

Several ideas for autonomous power can be found in the forum. The easiest solution for now will be to attach a truck or emergency generator (UPS) or simply an extension cord. So we need a possibility to plug it into the grid (1-phase might be too low, but let's go for that first as the vacuum system needs by far less energy in a mobile robot than in a conventional one).