Milker

Version vom 7. Juli 2013, 04:37 Uhr von Jan R.B.-Wein (Diskussion | Beiträge) (→Motivation for an autonomous milking ongoing robot (AMOR))

Motivation for an autonomous milking ongoing robot (AMOR)

An autonomous system results in the following dis-/advantages:

- + Indepence (no more need to be there to milk morning and evening, 7days/week)

- - Machine service increases

- + Technical knowledge increases, hence perhaps some other good robot ideas may evolve.

- + Cows/Goats/Sheep can decide themselves when to get milked.

- + Concentrated feed can be delivered automatically and according to milk delivered.

- - Animals' possible illness not realized early enough. => Action taken too late. => Animal could die.

- - Gathering at Milking robot leaves behind a lot of unusable muddy terrain at entrance (doors in general).

- - Higher complexity in separation of milk for calves, though of course possible.

- + Driving out and in of cattle no longer necessary as animals can get milked outside.

- + Less material required (much shorter vacuum and milk tubes as compared to conventional non-automated distributed [at cow/goat..] milking)

- ... and several others.

An ongoing system results in the following (dis-)advantages:

- - Higher complexity.

- + Independance of any external supplies.

** Water (heavily dependent on environment) ** Power ** Food (difficult, nevertheless this is planned for later revisions of AMOR)

- - Redundancy of susceptible subsystems (Electronics, in general: The more complex the system the higher the vulnerability).

- + Less cabling, water pipe laying and bundled maintenance (as you can wait for enough minor errors to accumulate before taking the system apart).

- ... and several others.

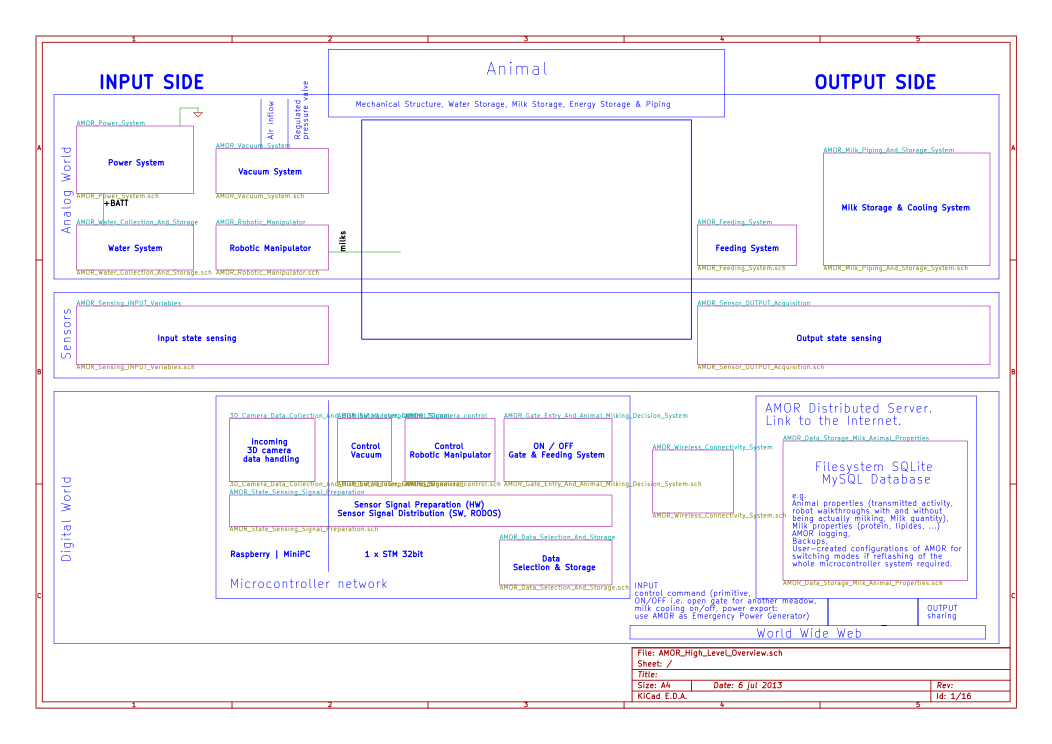

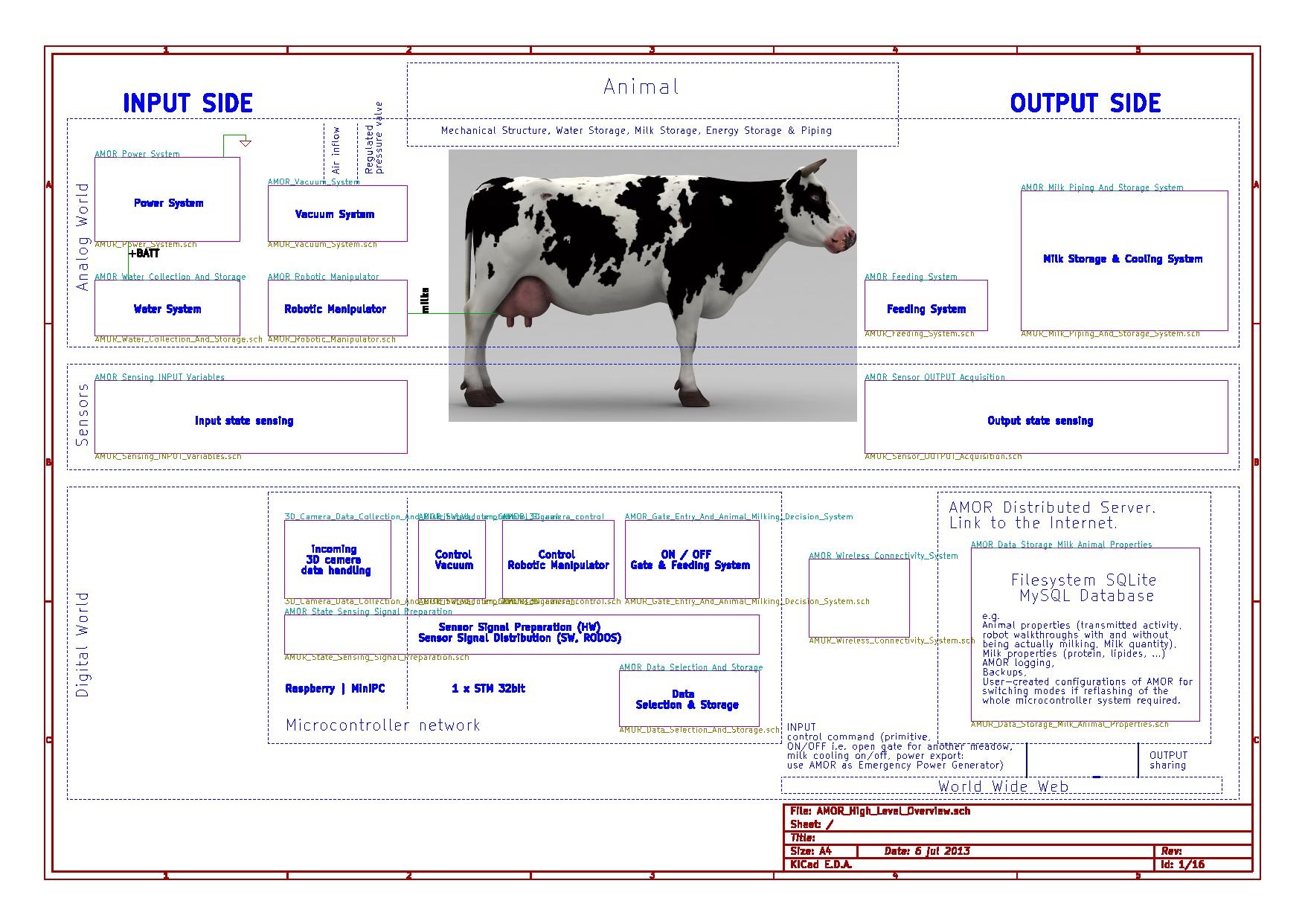

High Level Overview

Separation in Subproblems & Technological Difficulties

Our AMOR consists of several submodules:

- MECHANICAL CONSTRUCTION

- - Difficult to be robust, lightweight (for truck to lift) & cheap the same time.

- + Rain serves as a water supply and natural (ecologic) washing.

- VACUUM SYSTEM

- - Difficult to be flexible in frequency (provide user settings) and keep it simple at the same time.

- + Could be used for several other functionality than milking (doors, ...). => No hydraulics needed.

- Note: As the robotic manipulator should be flexible anyway, compressible air/vacuum could serve this purpose, too - stays the problem of vulnerability to leakage.

- Vacuum pumps.

- STORAGE CONSTRUCTION

- Milk

- Food

- Water

- Energy

- Database for animals milk (amount, properties, ...)

- Database for organization of the cow's fertile cycle, ...

- SENSORICS

- Milk properties (flow rate, derivations of that, TODO)

- Robotic manipulator (3D camera, washing mechanism)

- Animal within milking construction => Door states.

- ELECTRONICS

- Control of Doors.

- Control of Feeding (derived from amount of milk), but also accept some user constraints (lower / upper bounds for each type of food respectively).

- Control of Robotic manipulator (joints, gripper).

- Collection & storage of the stored animal & product data.

- SOFTWARE

- Microcontroller programs capable of controlling at least two AMOR system blocks (stacked next to each other).

- compare ELECTRONICS.

Revisions & Power system

Power system 100 kW inverter is planned for late August or early September, the AMOR power system & basic prototype for Autumn. [1]

Discussion

Feel free to post critiques or technical stuff here - alternatively use the forum, even though currently I think it's much easier and more on focus to discuss here directly - or under tab "talk". --Jan

- Topic

- Answer

- Another post

- next topic

- answer

- ..